On July 13, 2023, Baoding Hongcheng Converter Manufacturing Co., Ltd. successfully won the bidding for painting production line rectifier power supply equipment in Chongqing Changan Yubei Factory replacement and green intelligent upgrade construction project with complete design, manufacturing, installation, commissioning, after-sales system and good corporate reputation.

Yubei Factory of Changan Automobile Co., Ltd. is the birthplace of Changan autonomous cars and the first autonomous car production base of Changan.

Factory was established in October 2004, covers an area of about 750 mu, construction area of about 255 mu.

The total investment of the factory is 2.8 billion yuan, and the annual designed production capacity is 280,000 units, which has made outstanding contributions to the sales of Chinese brand cars.

The factory has two bases (Yubei Base, fish mouth base), six functional departments and four process workshops, employing a total of more than 8,000 people.

The factory has been committed to the construction of environmentally friendly enterprises, vigorously promote technological innovation, and actively carry out energy saving, emission reduction and consumption reduction in the production process as well as ecological design research work such as product fuel economy, health and safety.

The factory continues to carry out research on the core technology of green products, develop energy-saving technology, and raise health and environmental protection to a strategic height. In terms of air quality control in the car and the control of prohibited substances, through the establishment of standard system, test capacity building, upstream and downstream consistency control and other measures, It has formed a technical advantage suitable for Changan Automobile and priority over the domestic industry.

At the same time, in the field of green manufacturing, major breakthroughs have been made in the core key technologies and applications such as the all-robot + large-proportion circulating air painting process and the cleaning and purification of VOC exhaust gas in the painting room, and a demonstration green painting production line for auto body in Chongqing has been built, which has achieved significant energy saving in the auto body painting workshop and the emission of exhaust gas has reached a high level in the industry.

The factory green manufacturing starting point is high, the product ecological concept has been running through all aspects of the factory from the beginning of the factory, the selection of clean energy, the use of devices and production lines, and through continuous optimization and improvement, the company's green factory has been strengthened and improved.

On July 13, 2023, Baoding Hongcheng Converter Manufacturing Co., Ltd. successfully won the bid for rectifier power supply equipment in painting workshop of Geely Commercial Vehicle's new intelligent LCV Xiangtan Base technical transformation project with its complete design, manufacturing, installation, commissioning, after-sales system and good corporate reputation.

Hunan Geely Auto Parts Co., LTD. (Xiangtan Base of Geely Holding Group) is a wholly-owned subsidiary of Zhejiang Geely Holding Group and the first production base established in the central and western regions to support the development and strategic needs of the middle and western regions.

The company laid the foundation on January 20, 2006, and the first car rolled off the assembly line on December 25, 2006. In November 2008, the construction of the second phase of the project was completed, forming an annual production capacity of 100,000 vehicles; In September 2012, the new painting factory of the third phase project was built, with a fully automated spraying production line.

Hunan Geely Automobile Industry Co., LTD. (Xiangtan Company of Geely Holding Group) is a wholly-owned subsidiary of Zhejiang Geely Holding Group, one of the world's top 500 enterprises. The company is located in Xiangtan Jiuhua Economic Demonstration Zone, covers an area of about 840 mu, and has more than 2000 employees. 60 kilometers away from Changsha Huanghua Airport, close to Shangrui Expressway, in the Changzhutan city circle traffic core area, convenient transportation. At present, it has four advanced process production lines, and has introduced advanced automation equipment from Japan and Germany. The automatic transmission project is supported by dsi technology, the second largest Australian company in the world. The engine project covers 1.0L-2.0L, dual vvt, turbocharging and other technical products. At present, the company mainly produces Global Eagle gc7, Global Eagle New Vision and British Sea View three models, basically forming an annual production capacity of 200,000 vehicles.

Congratulations on the vigorous development of national brands!

On May 24, 2023, Baoding Hongcheng Converter Manufacturing Co., Ltd. successfully won the bidding for rectifier power supply equipment in the painting workshop of Geely Shangrao E51 Project with its complete design, manufacturing, installation, commissioning, after-sales system and good corporate reputation.

This E51 new energy pure electric van is a new launch of Geely commercial vehicles, which is an electric light bus type created for diversified needs such as urban distribution and logistics transportation.

The design adopts the forward development of a new lightweight cage body, providing users with two length options of 4.5m and 4.8m, of which the 4.8m version of the product has a length, width and height of 4845/1730/1985 mm, and an internal volume of 6 cubic meters.

Geely E5l new energy pure electric van is equipped with brand battery - Ningde Times lithium iron phosphate battery, the battery power is 30-60kWh, the use of high cycle LFP system, 5 years 200,000 km attenuation of 20% real and reliable, stronger stability, longer service life.

On June 30, 2023, Baoding Hongcheng Converter Manufacturing Co., Ltd. successfully won the bid for rectifier power supply equipment in painting workshop of Minshi Gantry ED project in Poland with its complete design, manufacturing, installation, commissioning, after-sales system and good corporate reputation.

Minth Group was founded in 1992 and listed on the Hong Kong Stock Exchange on December 1, 2005 (stock code: 00425), and now ranks among the top 100 automotive parts companies in the world. Minth Group has a global high-quality customer platform, is a global aluminum battery box supplier, a complete surface treatment supplier. At present, Minshi Group has 4 product lines, including plastic parts, metal body system, battery case and new business, 5 R&D centers, and more than 70 production plants worldwide, covering China, the United States, Mexico, Germany, Britain, France, Serbia, Czech Republic, Poland, Japan, Thailand and other countries. The group has nearly 20,000 employees and customers in more than 30 countries around the world. Services more than 60 automotive brands.

In 1992, Ningbo Minfu Machinery Co., LTD. (the predecessor of Minshi Group) was established in Xiaogang Industrial Development Zone of Ningbo City, which opened the prelude to the development of Minshi Group.

In 1997, after 5 years of development, Ningbo Minfu Machinery Co., Ltd. grew rapidly and integrated many other branches to establish Minshi Group.

In 2005, Minth Group was listed on the Hong Kong Stock Exchange.

In 2007, Minth Group's development involved overseas, the first acquisition of an overseas company (PTI) to establish a development fulcrum in the United States, and in the same year established a sales research and development base in Japan.

In 2008, MINTH Aapico, an overseas branch of Minth Group, was established in Thailand.

In 2009, Minth Group's production base in Mexico was established.

In 2012, Minth Group acquired CST and established the first production site in Europe.

In 2016, Ningbo Minshi Automotive Electronics Technology Co., Ltd. was established, marking Minshi officially involved in the research and development, production and sales of vehicle cameras and vehicle systems.

In 2018, the establishment of Minshi UK works.

In 2019, Minth Serbia factory was established.

In 2020, Minth Group is ready to launch four business divisions, layout: plastic products, metal and decorative products, aluminum products, battery box products.

According to the "Green Manufacturing List Announcement 2022" issued by the Ministry of Industry and Information Technology, three factories of Minshi Group: Ningbo Xintai Machinery Co., LTD., Qingyuan Minhui Auto Parts Co., LTD., won the green supply chain management enterprise; Shenyang Minergy Auto Parts Co., Ltd. won the national green factory. Up to now, Minth Group has ten plants awarded, all of which have achieved ISO14001 environmental management system certification.

In order to comply with the global sustainable development trend, Minth Group actively plans the future manufacturing industry in terms of energy conservation, low carbon, emission reduction and intelligence, establishes the Group Sustainable Development (ESG) Committee in 2022, and takes sustainable management as the Group's future strategic policy, and promotes green manufacturing. To help achieve the goal of carbon peak by 2030 and carbon neutrality by 2050.

Congratulations on the prosperity and development of national brands!!

On January 10, 2023, Baoding Hongcheng Converter Manufacturing Co., Ltd. successfully won the bid in Jianghuai Mengcheng multi-functional commercial vehicle relocation project painting workshop rectifier power supply equipment bidding with excellent product design capabilities, strong technical strength, solid manufacturing style, rigorous quality control mechanism, high-quality after-sales service, project team and good corporate reputation.

This project has an annual output of 30,000 multi-functional commercial vehicles, which is another large-scale application site of Hongcheng Silicon Carbide (SiC) module power supply after Nanning Union and Hefei Volkswagen.

The project adopts high-performance silicon carbide (SiC) module power supply (SiC 100A/400V) independently developed by Hongcheng Company. The product adopts the third generation semiconductor power chip with high power, low loss, high reliability and low heat dissipation performance. The integrated module power supply has more reliable operation, more energy saving, easier installation, easier debugging and more stable output. Higher cost performance.

In the future production process, it will bring extremely high value-added services in terms of power saving and paint saving, and help Jianghuai multi-functional commercial vehicles green, low-carbon, energy saving and efficiency development goals.

今年年初,湖北省生态环境厅发布印刷行业、表面涂装(汽车制造业)挥发性有机化合物排放标准等3项强制性地方标准的公告,标准实施日期定于2020年7月1日,与《挥发性有机物无组织排放控制标准》(GB 37822- 2019)全面执行日期为同一天。

据最新通知,湖北省新版《表面涂装(汽车制造业)挥发性有机化合物排放标准》延期执行,将于2021年1月1日起实施。

此标准中首次提出了,“苯系物”和“非甲烷总烃”的特别排放限值控制要求,其指标限值与北京地标一致,属全国最严限值。

标准规定了湖北省表面涂装(汽车制造业)挥发性有机化合物排放标准控制和监测、生产工艺和管理要求,以及标准的实施与监督要求。

与其他省(市)标准相比,湖北省《表面涂装标准》主要具有以下特点:

一是考虑到湖北汽车行业分布及臭氧污染防治重点区域,标准中首次提出了”苯系物”和”非甲烷总烃”的特别排放限值控制要求,属全国最严限值。特排限值具体执行时限、范围由各地级以上市人民政府规定,可满足全省不同区域对大气环境管理的差异化需求。

二是本标准充分结合国家《挥发性有机物无组织排放控制标准》( GB 37822- -2019 ),对汽车制造业VOCs无组织排放管控提出了全面要求,进一步提升行业无组织管控水平。

三是针对汽车制造业表面涂装工序中VOCs产生量较大的罩光漆喷涂工序,系统性提出了尾气收集及尾气处理效率的指标要求(工艺尾气治理设施对非甲烷总烃的处理效率不低于90% ) , 为削减汽车行业VOCs排放明确相关条件。

允许排放浓度具体情况:苯要严于广东、天津、重庆、上海、江苏、河北、浙江、福建、陕西等省市现行地方标准,甲苯与二甲苯均严于广东、天津、重庆、河北、陕西等省市现行地方标准;苯系物严于广东、重庆、上海、浙江等省市现行地方标准;非甲烷总烃严于河北、浙江、福建等省现行地方标准。

据悉,本标准原定实施日期为今年7月1日,鉴于2020年初全球新冠肺炎疫情影响,湖北省大部分汽车企业处于停产状态,相关企业VOCs治理设施/设备无法实施采购、相关进口设备无法按时到货安装。难以在本标准原定的实施日期7月1日前完成提标改造。考虑到全省环境保护工作的实际情况,为促进企业疫后复工复产,经省市场监管局、省生态环境厅研究并报请省人民政府批准,将本标准的实施时间延期至2021年1月1日。

第六届汽车车身涂装工程发展论坛圆满落幕,共讨汽车涂装未来发展趋势

2018年7月2-3日,车身工程系列论坛 Car Body Painting 2018 第六届汽车车身涂装工程发展论坛在上海卓美亚喜玛拉雅酒店圆满落幕,保定宏诚变流器作为本届论坛的赞助商之一参与了此次会议,并进行了电泳涂漆安全节能解决新方案——HC-MACS(IGBT模块电源)应用的演讲。

本次大会聚焦智能化绿色涂装工厂、新型材料全新喷涂解决方案、涂装车间节能降耗、绿色环保、数字化工厂规划等车身涂装新工艺、新设备、新技术及面临的机遇与挑战,吸引了大会通过演讲报告、峰会讨论、展品展示等多种形式为供应商和技术专家们提供了以技术交流为基础,商务对接为核心的绝佳平台。

本届论坛吸引了众多优秀原始设备供应商以及知名主机厂家等300多名工程技术人员莅临现场。现场共进行了17场主题演讲, 共17位演讲嘉宾们积极分享各自多年的实践经验和行业的最新技术知识。会议期间还进行了2场嘉宾讨论,多位行业知名人士就“未来汽车涂装智能制造之路”和“汽车涂装车间节能环保精益对策"这两个问题进行讨论。

保定宏诚变流器本届论坛演讲的内容为电泳涂漆安全节能解决新方案——HC-MACS(IGBT模块电源)应用。MACS(IGBT模块电源)应用技术每个IGBT模块对应1只阳极管的供电方式,系统自动跟踪车身位置,以单只阳极管为最小单元,对车身多区域的电压电流可调,达到漆膜均匀的效果。MACS(IGBT模块电源)具有以下应用特点:

1、设备故障不影响生产

2、电泳膜厚更均匀,可控制在1-3u

7、加车型、增加产量,增容成本低

3、100平方电泳面积可节省0.5Kg漆

4、100平方电泳面积可节省1度电

5、阳极管限流保护及数字监控,寿命延长3-5年

6、功率因数高达0.96-1,节省了无功补偿装置

8、运行噪音小。

宏诚变流器把IGBT开关电源最新技术率先应用在涂装阴极电泳上,前后5年时间攻克在大功率开关电源的世界技术难关,并取得世界领先水平。

本届论坛的气氛很活跃,现场互动很多,设备集成商与主机厂一起探讨最新的设备与技术,非常具有启发性。同时也涵盖了我们非常关注的最前沿的智能化、自动化设备话题,对轻量化的探讨也很深入,对于我们来说是一次非常好的学习机会。

以“智造”来定义自己的零跑汽车日前于杭州举办了一场声势浩大的合作伙伴大会,并在会上公布了对旗下产品的未来规划。其中首款主打产品S01定位为两门四座纯电动轿跑车,新车的设计非常独特,有一股美式肌肉车的味道。其核心的电驱、电控系统将全部由零跑自主研发设计,电池部分使用与特斯拉同规格的18650电池,由比克提供电芯并自行Pack组装。新车的预计最大续航里程为360km,NEDC工况下为250km。

零跑S01的车身尺寸不大,长宽高分别为:4075*1760*1380mm,轴距2500mm,看起来比较小巧,比较夸张的前脸造型可以让人非常容易记住它。

新车的配置非常全面,LED大灯、无框车门、运动座椅等非常时尚抢眼。科技配置上同样不含糊,车内配有两块大屏,支持车机互联、远程控制、网络电台/音乐等。此外,零跑S01量产车型将会达到L2级别的辅助驾驶水准,提供自适应巡航、车道偏离预警、车道保持、防疲劳驾驶等安全配置,未来还将通过软件升级,达到L3级别。

零跑来自哪里? 要做什么?

零跑汽车成立于2015年,董事长朱江明曾历任大华股份副总裁、副董事长、杭州摩托罗拉总经理等职务,并直言其更擅长做电子产品。因此零跑这家新生的造车企业也就被深深的烙下了IT风格印记,而在实际的操作过程中,零跑也确实做到了这一点,其旗下所有部门负责人中,除研发、供应链两个与传统车密不可分的部门外,其他负责人均出身IT企业。

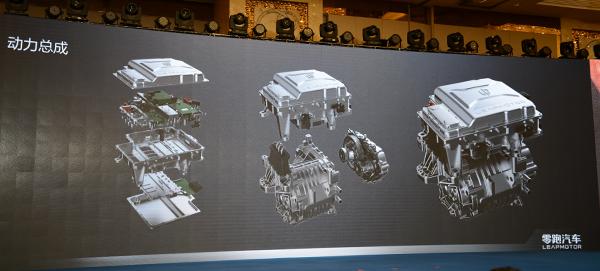

在投身于智能电动汽车及其关键技术的研发后,零跑汽车迄今已取得了一系列阶段性成果:成功研发零跑Heracles集成式电驱系统等核心零部件并已具备量产能力;公司Pre-A轮融资顺利完成,零跑汽车成为国际知名投资机构红杉中国领投的首家新能源汽车企业;首款量产车型零跑S01高标准通过国家整车质量检测试验,并在黑河顺利完成高寒试验,表现出良好的综合性能和整车可靠性。

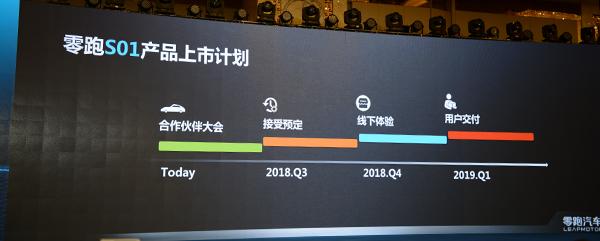

目前零跑汽车首款车型S01已经基本处于完备状态,预计在2018年第三季度开始接受预订,并将于2019年初开始陆续交车。零跑将会采用时下流行的城市体验展厅+线上销售,配合维修店面的销售服务策略,先期主要面对京沪、杭州、广州、深圳等一线城市。

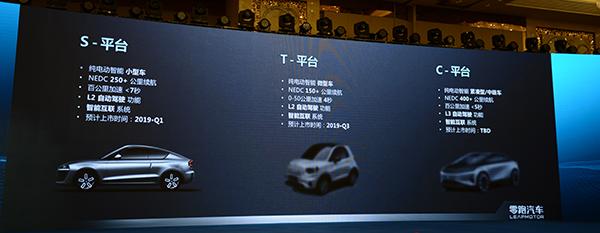

而在产品的研发方面,零跑准备了三大平台,不同路线的产品计划。其中S平台主要用于小型纯电动汽车,T平台为纯电动微型车,C平台则对应紧凑级/中型纯电动汽车。全线产品将标配L2级别智能辅助驾驶功能,同时具备随时升级到L3级别的硬件储备。

得益于背后处于国际一流安防技术企业大华股份的支持,零跑在车载智能系统、人脸识别系统上具有先天的优势。以零跑S01为例,车辆将搭载9个摄像头、12组超声波雷达、1个毫米波雷达以及HDCVI和深度学习技术。除了我们现在比较熟悉的智能辅助驾驶功能外,S01还可以实现720°的环视影像系统、一键自动泊车、人脸识别(通过识别驾驶员的人脸特征,定义车辆的座椅、方向盘位置,以及自动搜寻喜爱的音乐、兴趣点等,目前对私车辆可以最多储存10组人脸记忆)。

零跑的目标群体是谁?

零跑将其消费群体定义为新生代用户,即不受传统消费理念束缚,渴望新鲜体验,喜欢创新和科技类产品的年轻群体。

零跑汽车市场部负责人表示,零跑S01会以“潮牌”的推广方式走向市场,打造自己的与众不同。再给你全新出行体验的同时,还能不忘享受生活、享受科技带来的乐趣。

未来零跑汽车将会以城市体验中心+社区维修点+服务中心销售服务模式率先进入一批一线城市,这种模式也是由电动汽车行业领军人物特斯拉首先开创,并证明了比较成功和成熟的现代化新零售模式。

不过对于零跑汽车来说,除了产品、营销外,还有很多方面需要努力,包括对生产资质的积极申请、代工的合作方选择、如何保证产们品供应链持续完整以及成本控制等对一家新生造车企业来说非常重要的因素。随着政府对电动汽车的补贴力度逐渐降低,行业内的产品水平飞速发展,零跑能不能在一个对的时间,推出对的产品,对其来说至关重要。

Address:Baoding City, Lianchi District, Shenzhen Park, Liandong U Valley, Building 16

Email:hc@hong-cheng.cn

Hotline:4001505528 Technical Support:4001505528

Copyright © HONGCHENG Converter Manufacturing Co., LTD.

Wechat

Wechat

Mobile site

Mobile site